|

|

|

|

| The

summer of 2003 - The project halts due to problems with the

soft bended lines of the "nose" |

I made a few tries with different techniques,

but none of them made me satisfied.

|

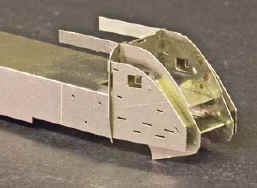

One of

the "noses" on the first mockup - far away from

good :-(((

|

|

|

|

|

|

|

|

|

|

|

|

| 2003-2004

|

|

|

While

the project was resting there was other upcoming projects,

the construction

of the body of a diesel engine and a

station bulding with an advanced brick patttern.

To solve the challenge with these items I decided to learn

more about how to make photo etched details.

This technique was suiting me fine and the results with the

scratchbuilt engine and the building gave me new ideas how to

continue with the Regina project.

|

|

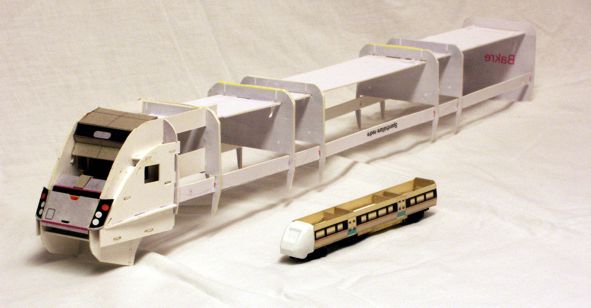

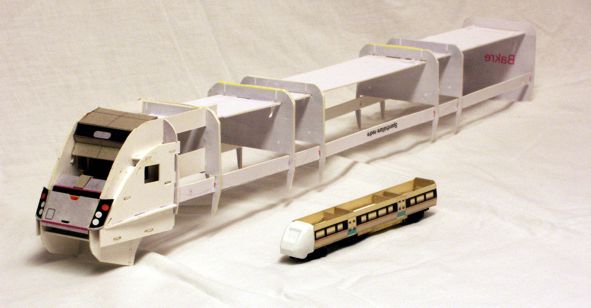

My

idea was to build the body of the EMU as a frame built

ship and the "nose" sliced to reduce the amount of

bent areas.

In N-scale that would mean many tiny details, some of them

should be bent and then fitted together. To prevent mistakes

with measures on the final sheet I built cardboard models to

check all measurments.

The models were built in scale 1:40 which made it more easy

to cut out things in cardboard |

|

|

|

|

|

|

To

an N-scale modeller a 1:40 model is gigantic

|

|

|

|

|

|

| September

2005

|

|

|

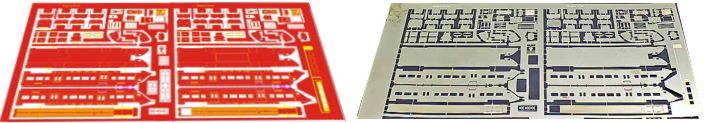

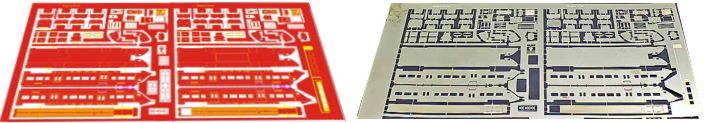

Many

hours was spent at the computer.

I use Corel Draw to make all drawings for the etchings.

The file was prepared for printing with color separations to

acheive the different grades of etching.

|

|

When

everything was ready the files were sent to a service bureau

to make two negative films for the photoetch process which

laters was made by another firm.

After not more than a week I had the new etched sheet on my

workbench |

|

|

|

|

|

|

| The

original Corel Draw file |

The

final photoetched metal sheet. (A3 format) |

|

|

|

|

|

|

|

|

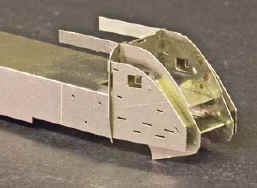

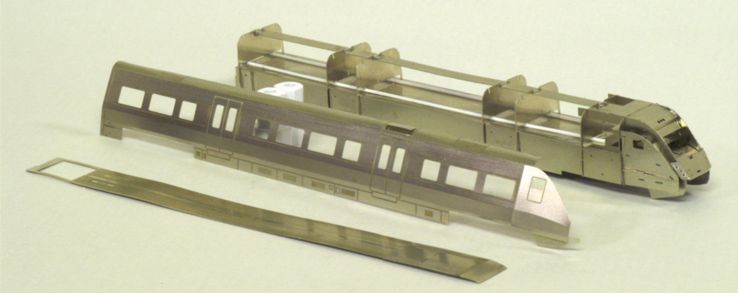

| The

intricate details of the front was made in two blocks |

and

here are the two blocks joined. |

|

|

|

|

|

|

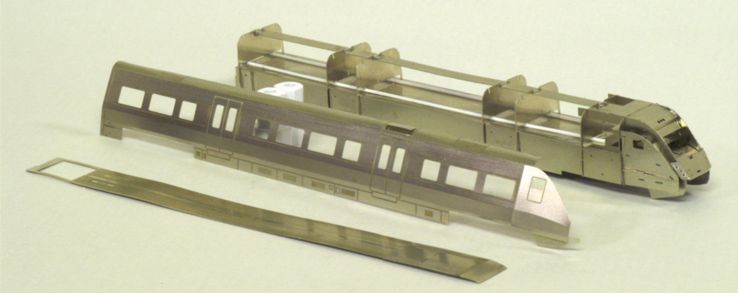

The main parts

of the EMU body,

the framework, one of the wagon sides and the roof

|

|

|

The

both wagons while testing the fitting of the roof details

|

|

|

|

|

|

While building the bodys this way, the bent areas was reduced

to a couple of very small areas in the front. I used small

pieces of air drying clay (Das Pronto) to form the areas

|

|

After drying, the areas was sanded to form an almost correct

smooth area. |

|

|

|

|

|

|

|

|

|

|

The plow on the underside of the front is made of styrene

sheet which are glued togheter and then grinded to get the right

shape.

|

Micro Train couplings are fitted at the front ends of the

EMU |

|

|

|

|

|

|

|

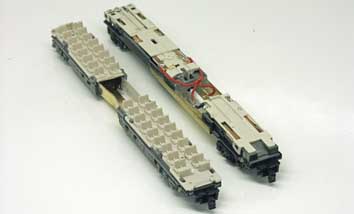

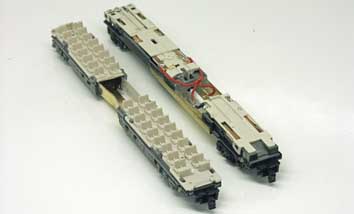

The Kato JR 681 Thunderbird train

|

The

two extended chassis, one motorized and one dummy.

They are made from Kato chassis which are cutted and then

extended to fit to this rather long EMU.

|

The extension of the motorized Kato 11-102 chassis is

described in part two of

this article.

The dummy chassis comes from a Kato Thunderbird train

which is extended in a similar way. |

|

|

|

|

|

|

|

|

|

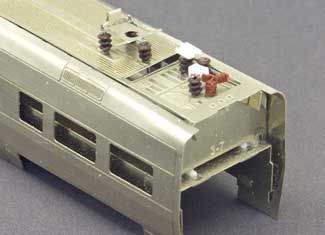

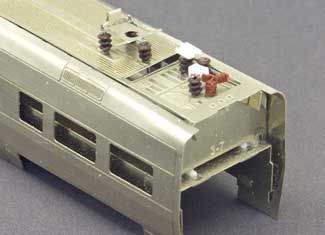

Some roofing details.

|

|

The patterned details are from the etched sheet.

The isolators are from a set of Sommefeldts isolators and

the pantograph is picked from a scrapped loco.

|

|

|

|

|

November

2005

Another picture of the two wagons side by side.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Next

chapter, painting --->

|

|

|

|

|

|

Top

Top

|

|